The water for injection preparation system is a key GMP system. The multi effect distiller is the key equipment of the most widely used WFI system at present. BIOCELL's multi effect distilled water machine and multi column distillation plant adopts high temperature and high pressure operation to ensure stable production of pyrogen free water for injection. The water for injection produced by the multi effect distilled water machine fully meets the requirements for water for injection generation in the current American Pharmacopoeia, European Pharmacopoeia, Japanese Pharmacopoeia and Chinese Pharmacopoeia.

| Specification | Output of Distilled Water (L/h) | Steam Consumption (kg/h) | Purifed Water Consumption (L/h) | Cooling Water Consumption (L/h) | Overall Dimension LxWxH (mm) |

| LD (S) 100-4 | >100 | 30 | 120 | 50 | 900x700x2000 |

| LD (S) 200-4 | >200 | 60 | 240 | 100 | 1000x800x2000 |

| LD (S) 300-4 | >300 | 90 | 360 | 150 | 1100x800x2200 |

| LD (S) 500-4 | >500 | 150 | 600 | 250 | 1400x900x2500 |

| LD (S) 500-5 | >500 | 130 | 600 | 100 | 1600x900x2500 |

| LD (S) 1000-5 | >1000 | 240 | 1100 | 200 | 1700x1100x3100 |

| LD (S) 1000-6 | >1000 | 190 | 1100 | 20 | 2100x1100x3100 |

| LD (S) 1500-5 | >1500 | 350 | 1670 | 290 | 2700x1100x3700 |

| LD (S) 1500-6 | >1500 | 290 | 1670 | 90 | 3200x1100x3700 |

| LD (S) 2000-5 | >2000 | 440 | 2200 | 210 | 3200x1100x4000 |

| LD (S) 2000-6 | >2000 | 390 | 2200 | 110 | 3600xI100x4000 |

| LD (S) 3000-6 | >3000 | 810 | 3300 | 150 | 4000x1200x4100 |

| LD (S) 4000-6 | >4000 | 880 | 4400 | 200 | 4300x1300x4200 |

| LD (S) 5000-6 | >5000 | 980 | 5500 | 250 | 4600x1400x4200 |

| LD (S) 10000-6 | > 10000 | 2250 | 11000 | 450 | 4900x1600x4800 |

1. Pharmaceutical Industry

Multi-Effect Water Distillers are essential for producing Water for Injection, which is critical for the preparation of intravenous drugs and vaccines.

2. Biotechnology

High-purity water from MEDs is crucial for preparing culture media and solutions used in biotechnological processes.

3. Medical Device Manufacturing

MEDs provide the high-purity water needed for cleaning and sterilizing medical devices, ensuring they are free from contaminants.

4. Cosmetics and Personal Care

Multi-Effect Water Distillers produce the purified water necessary for formulating safe and high-quality cosmetics and personal care products.

5. Food and Beverage Industry

High-purity water from MEDs is used as an ingredient in beverages to ensure product safety and quality.

6. Laboratory and Research

MEDs supply the high-purity water required for various analytical procedures, ensuring accurate and reliable results.

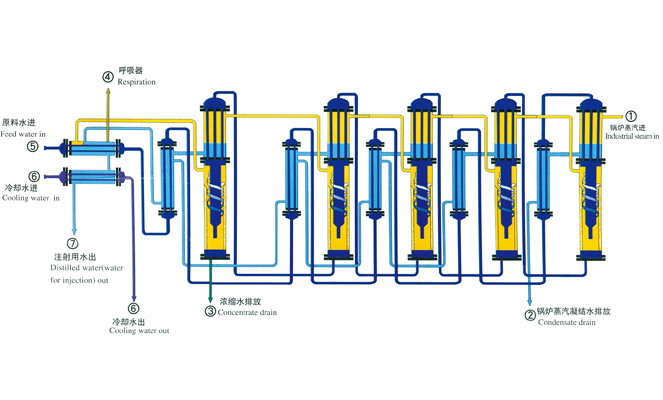

The working principle of the multi effect distilled water machine is that the fully heated raw water is evaporated and condensed by multi effect to remove non condensable gas and impurities, so as to obtain high-purity distilled water. To ensure the quality of distilled water, the raw water must be pretreated. Because of multiple effect evaporation, the heat of the multi-effect water distiller is fully utilized. Each effect evaporator adopts the principle of vertical tube type falling liquid film evaporation, plus a special structure of feed water distributor, so that the feed water of the multiple effect distillation can form a film and flow evenly in the tube. Like other pharmaceutical water purification system, the multi effect distilled water machine eliminates the dry wall phenomenon caused by uneven distribution of local feed water, greatly improving the evaporation efficiency. The multi effect distilled water machine has the characteristics of small size, light weight, large water yield, and good water quality stability.

Superior multi effect distiller with unique three-stage separation mode to fully ensure the quality of produced water.

New expansion process and multi column distillation plant, effectively avoiding cross contamination.

PLC+HMI full-automatic control mode.

Fully comply with GMP, USP and cGMP requirements.

Phone:

E-mail:

Address:

Room 1904, Building 10, No. 218, Jiqingmen Street, Jianye District, Nanjing, Jiangsu, China