Water is the lifeblood of countless industries, from pharmaceuticals to power generation. But not just any water will do — ultra-pure water is often a non-negotiable requirement. This is where an All-in-One Multi-Technology RO-EDI Plant comes into play. Combining reverse osmosis (RO) with electrodeionization (EDI) in a single system, these plants offer unparalleled water purity, efficiency, and sustainability. Let’s dive into what makes these systems so powerful and why they’re rapidly becoming the gold standard in water purification.

Reverse osmosis (RO) is a powerful water purification process that removes dissolved solids, organic compounds, and contaminants from water by pushing it through a semi-permeable membrane. This membrane has incredibly tiny pores that allow water molecules to pass through while blocking larger particles, such as salts, bacteria, and heavy metals.

RO works by applying pressure to the incoming water, forcing it through the membrane and leaving behind impurities in a concentrated reject stream. This process is especially effective at reducing common contaminants like chlorine, lead, arsenic, and dissolved minerals.

However, while RO removes up to 99% of dissolved solids, it may not catch every trace ion or volatile organic compound. For applications requiring ultra-pure water, RO alone isn’t enough — and that’s where EDI comes into play.

Electrodeionization (EDI) is an advanced water purification technology that takes the process a step further by using electricity to remove residual ions from water. After RO treatment, EDI acts as a polishing stage, stripping out remaining charged particles to achieve ultra-high purity.

EDI systems use a series of ion-exchange membranes and resin-filled chambers. When an electrical current is applied, positive and negative ions are attracted to oppositely charged electrodes, pulling them out of the water stream. The ion-exchange resin helps speed up this process, and the continuous electrical regeneration eliminates the need for chemical regeneration, making EDI a safer and more sustainable option.

The result? Consistently pure water with resistivity levels up to 18.2 MΩ·cm, meeting even the strictest quality standards for industries like pharmaceuticals, power generation, and semiconductor manufacturing.

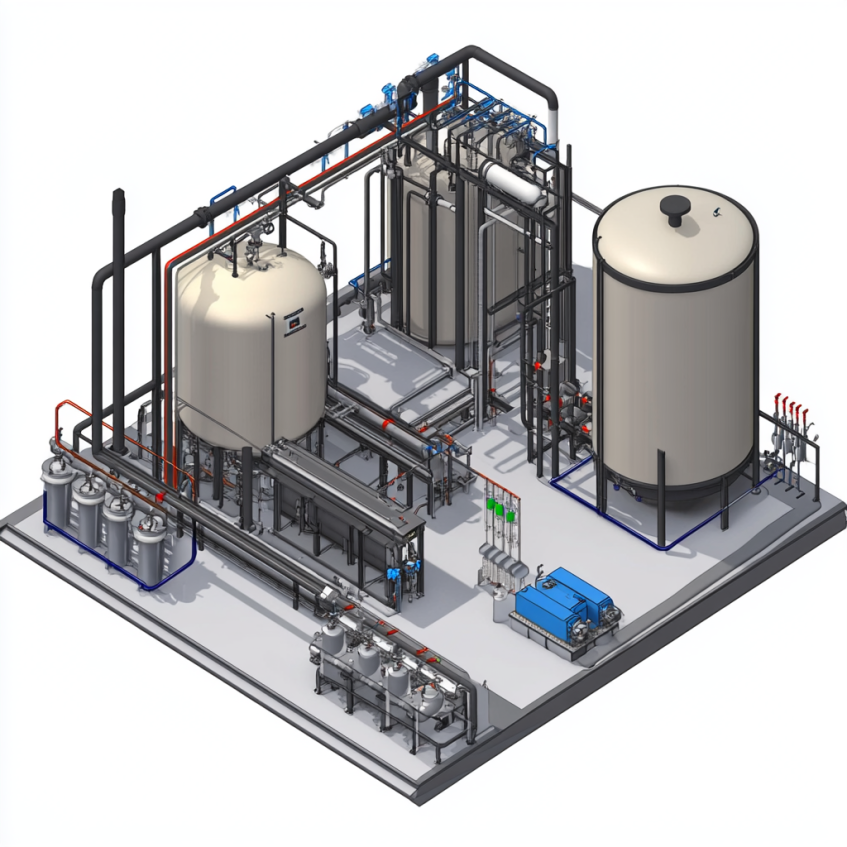

RO Membranes: The first line of defense against dissolved impurities.

EDI Modules: The polishing step, eliminating remaining ions.

Pre-Treatment Systems: Protecting RO membranes from fouling.

Post-Treatment Processes: Final adjustments to meet specific water quality requirements.

In an RO-EDI plant, the water purification process begins with pre-treatment, where filters remove sediments, carbon filters eliminate chlorine, and softeners or antiscalants prevent scaling. This protects the reverse osmosis (RO) membranes, which then use pressure to push water through a semi-permeable membrane, removing up to 99% of dissolved salts, minerals, and contaminants. The partially purified water flows into the electrodeionization (EDI) system, where electricity and ion-exchange resins work together to strip away remaining ions. The EDI system continuously regenerates without chemicals, delivering ultra-pure water suitable for high-precision industries like pharmaceuticals and electronics manufacturing. This combination of RO and EDI ensures reliable, sustainable, and cost-effective water purification.

Ultra-pure water is crucial for drug formulation, laboratory work, and sterilization.

High-purity water prevents scaling and corrosion in boilers and turbines, boosting efficiency and lifespan.

Even trace contaminants can ruin semiconductor production — RO-EDI ensures pristine water for wafer fabrication.

Pure water enhances product quality and ensures compliance with hygiene standards.

The All-in-One Multi-Technology RO-EDI Plant is more than just a water treatment system — it's an investment in efficiency, reliability, and sustainability. By combining the strengths of RO and EDI, these systems offer unparalleled water purity, lower operating costs, and minimal environmental impact. Whether you’re in pharmaceuticals, power generation, or manufacturing, an RO-EDI plant is the smart choice for your high-purity water needs.

This is the first one.