The water for injection system equipment conforms to the GMP verification requirements of drug manufacturing specifications and the standard provisions of Chinese Pharmacopoeia. Water for injection is distilled water or deionized water made by distillation and weighed distilled water. In order to effectively control microbial contamination and control bacterial endotoxin at the same time, the design and manufacture of purified water and water for injection system has two major characteristics: first, a disinfection/sterilization device is used in the system; The second is the pipeline distribution system for the circulation of water pipes.

Water for injection should be prepared, stored, and distributed in such a way as to prevent microbial growth and contamination. The materials used for storage tanks and delivery lines should be non-toxic and corrosion-resistant. Dead corners and blind pipes should be avoided in pipeline design and installation. Cleaning and sterilization cycles for storage tanks and pipes should be specified. The vent of the water storage tank for injection shall be equipped with a hydrophobic sterilizing filter that does not shed fibers. The storage of water for injection can be insulated above 80℃, insulated circulation above 70℃ or stored below 4℃.

The pipes used in the pretreatment equipment of the water for injection system are generally made of ABS engineering plastics, PVC, PPR, or other suitable materials. However, the distribution system of purified water and water for injection should adopt related pipeline materials such as chemical disinfection, pasteurization, and thermal sterilization, such as PVDF, ABS, PPR, etc. It is best to use stainless steel, especially model 316L. Stainless steel is a general term, strictly divided into stainless steel and acid-resistant steel two. Stainless steel is resistant to atmospheric, steam and water, and other weak medium corrosion of steel, but not resistant to acid, alkali, salt and further chemical corrosive corrosion of steel, and has no rust. The purified water and water for injection prepared by the water for injection preparation system must be distributed in strict accordance with the 2015 edition of Chinese Pharmacopoeia, so the distribution of water for injection should be carried out in a scientific and rigorous method.

According to the requirements of the 2015 edition of Chinese Pharmacopoeia on the preparation system of water for injection, as well as the water quality of the pharmaceutical industry in China and other parts of the country, Best has independently developed and produced a series of water for injection preparation systems with advantages of stable effluent water quality and high-cost performance and can be customized according to customer requirements to meet the requirements of GMP verification.

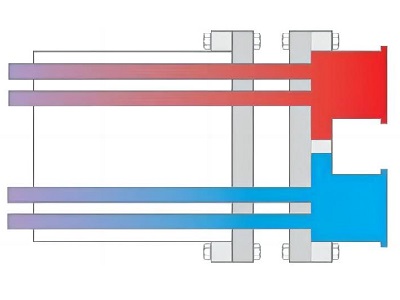

● System structure: falling film evaporation, spiral separation, built-in preheating, double tube plate structure, greatly reduce stagnant water;

● System control: Based on years of experience, Best has developed an automatic control system for the preparation of water for injection, automatic operation of equipment, cleaning, online testing, etc., and the core components are all famous brands at home and abroad.