The pharmaceutical water used for medical device industry is high-purity sanitation water, mainly used for cleaning, diluting and other production processes. The design of the equipment for preparing pharmaceutical-grade purified water takes into account the convenience of management, reasonable design for sampling points, data inspection, and consumables replacement. Through the management panel, the system principle and water quality data can be viewed, achieving stable operation and water quality safety.

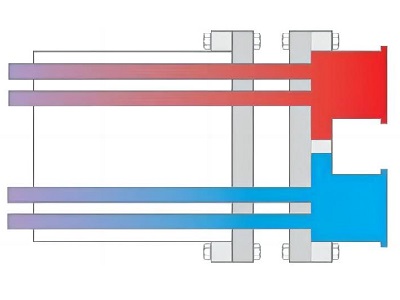

The purified water equipment system includes pre-treatment system, secondary RO system, EDI system, storage system, distribution system, disinfection system, electrical, control and other auxiliary systems. It can effectively remove various salts and impurities in the water, and continuously and stably produce purified water that meets the internal control indicators or pharmacopoeia requirements of the enterprise. The water quality of the produced water meets the customer's production water requirements and conforms to GMP, FDA and other certification requirements.

The overall humanized design of the pharmaceutical purified water systems, modular installation, small footprint, simple operation and easy maintenance, stable operation, and high efficiency and energy saving.

High level of integration, easy to expand, and increasing the number of membranes can increase the processing capacity.

High degree of automation, immediate self-stop in case of failure, and automatic protection function.

The membrane components are made of composite membrane rolls, showing higher solute separation rate and throughput rate.

Low energy consumption, high water utilization rate, and low operating costs.

Reasonable structure, small footprint.

Advanced membrane protection system, the concentrated water can automatically flush the membrane surface pollutants to extend the membrane life when the equipment is turned off.

The system has no fragile parts and requires no large amount of maintenance. It can run effectively for a long time.

The equipment is designed with a membrane cleaning system and a anti-scaling system.

The pharmaceutical water systems are based on the preparation, storage, and output of purified water and injection water production equipment. Through the optimized combination of each functional module, the high performance and quality of the entire system are ensured, so that the product water completely meets or exceeds the water quality standards of purified water and injection water.

We should monitor and manage the operation and maintenance of equipment according to the requirements of verification and documents. Ensure that the system's operating parameters are within the range of confirmed operating parameters of the equipment.